Lightweight blocks are a popular choice in construction due to their ease of handling, excellent thermal insulation, and reduced structural load. In Pakistan, two types of lightweight blocks dominate the market:

1. Foam-Based Lightweight Blocks (CLC Blocks): Made using a foaming agent, cement, and water.

2. Aggregate-Based Lightweight Blocks: Made with lightweight aggregates like pumice stone, fine aggregates (crush or sand), and cement.

This blog explores the ratios and formulations to produce each type of lightweight block effectively.

—

1. Foam-Based Lightweight Blocks (CLC Blocks)

Foam-based lightweight blocks, also known as Cellular Lightweight Concrete (CLC) blocks, are produced using a combination of cement, water, and a foaming agent.

Ingredients

Cement: Ordinary Portland Cement (OPC)

Water: Clean and potable water

Foaming Agent: Synthetic or protein-based foam

Ratio and Formulation

1. Cement to Water Ratio: 1:0.5 to 1:0.6 (adjust for consistency).

2. Foaming Agent: Add 1–2% by weight of cement or as recommended by the supplier.

Production Process

1. Mix cement and water to create a smooth slurry.

2. Use a foam generator to prepare foam and gently mix it into the slurry.

3. Ensure even distribution of foam while avoiding bubble collapse.

4. Pour the mixture into molds and allow it to set.

5. Cure the blocks using steam or water for 7–28 days to achieve the desired strength.

Key Features

Density: 600–800 kg/m³

Thermal Insulation: High

Compressive Strength: 3–7 MPa

—

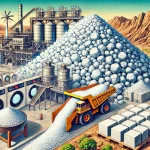

2. Aggregate-Based Lightweight Blocks

These blocks rely on lightweight aggregates like pumice stone combined with fine aggregates and cement to achieve their reduced weight.

Ingredients

Cement: Ordinary Portland Cement (OPC)

Pumice Stone: Coarse aggregate

Fine Aggregate: Sand or crushed stone

Water: Clean and potable water

Ratio and Formulation

1. Cement: Fine Aggregate: Coarse Aggregate Ratio: 1:2:3 or 1:1.5:3 (depending on density and strength requirements).

2. Water to Cement Ratio: 0.4 to 0.5 (adjust for workability).

Production Process

1. Thoroughly mix the dry ingredients (cement, sand, and pumice stone).

2. Gradually add water to create a homogenous mix.

3. Pour the mixture into molds and compact it to remove air pockets.

4. Allow the blocks to set for 24–48 hours before demolding.

5. Cure the blocks in a humid environment for 7–28 days to ensure proper strength.

Key Features

Density: 900–1200 kg/m³

Thermal Insulation: Moderate

Compressive Strength: Varies based on mix design

—

Comparison and Applications

Both types of lightweight blocks are suitable for various construction applications, including non-load-bearing walls, partition walls, and insulation layers.

—

Conclusion

Lightweight blocks offer innovative solutions for modern construction by reducing structural load and enhancing energy efficiency. Whether using foaming agents or lightweight aggregates like pumice stone, careful attention to the ratios and curing process is essential to ensure quality and performance.

By understanding the specific requirements of your project, you can select the right type of lightweight block and achieve the desired balance between strength, weight, and insulation.

For any questions or to source high-quality raw materials like pumice stone or foaming agents, feel free to reach out to Tradeworth International!